QIC Assess -

Take Control of Pipeline Corrosion, Simplify Compliance and Enhance Safety

Leading the Way in Internal Corrosion Integrity Management

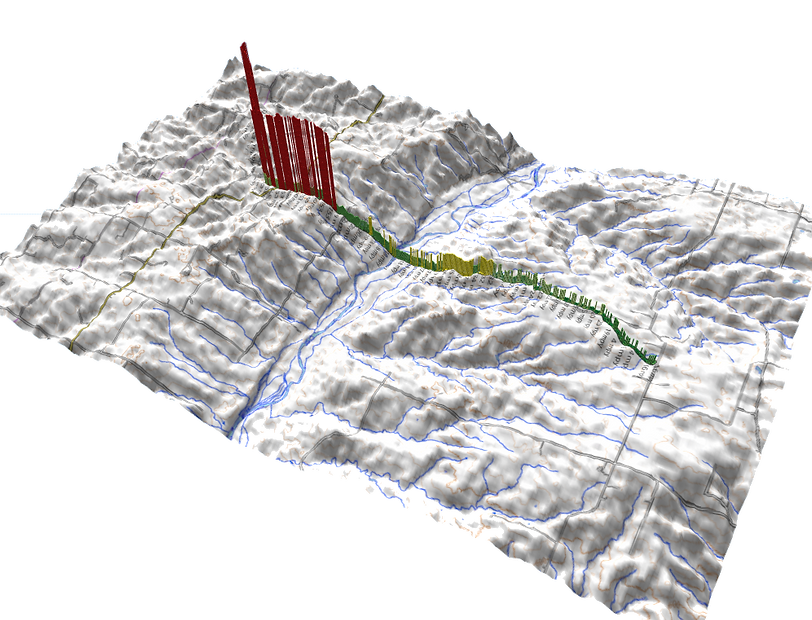

QIC Assess utilizes advanced, mechanistic three-phase pipeline modeling powered by the industry-leading OLGA-S correlation within SLB's PIPESIM software.

This sophisticated modeling accurately simulates multiphase flow dynamics (oil, water, gas), enabling precise prediction of pipeline corrosion threats, liquid holdup, water-wetting conditions, and localized corrosion susceptibility.

By leveraging these high-fidelity simulations, QIC Assess ensures comprehensive internal corrosion hazard classification and optimally targeted mitigation recommendations—delivering robust pipeline integrity management aligned with modern, performance-based regulatory requirements.

Trusted Integrity Solutions for Over Three Decades —Continuous Evolution, Exceptional Results

QIC Assess empowers pipeline operators to achieve industry-leading internal corrosion hazard classification and targeted mitigation strategies.

Our proven methodology, evolved since 1994, laid the groundwork for NACE ICDA standards for wet-gas and dry-gas pipeline systems—ensuring compliance, operational efficiency, and exceptional safety performance.

QIC Assess Image by TPA

Transform Your Pipeline Management Program—

QIC Assess + Corrosion Management Plan (CMP-IC)

Affordable at $1,500 / Pipeline

Affordable, actionable insights delivering optimal asset integrity and peace of mind for all pipeline operating sectors:

-

Multi-Phase Production Gathering / Midstream Gas / Gas Transmission / Crude Oil / NGL / Refined Liquid Products

YouTube / Shorts

Precision in Prevention: How QIC Assess Transforms Corrosion Hazard Management

Discover our collection of quick, insightful YouTube Shorts podcasts, offering valuable highlights and expert guidance on the QIC Assess platform for pipeline integrity and corrosion management.

QIC Assess -

Download Sample Reports

Wet-Gas Gathering

Multi-Phase Gathering

Wet-Gas

ANNOTATED

Crude Oil

Transmission

QIC ASSESS / CMP-IC

Simplified Project Implementation Model

Revolutionizing Corrosion Hazard Profiling with Advanced Mechanistic Pipeline Modelling

Accelerated Corrosion Failures Triggered by Non-Steady-State Operations Accounts for 87% of all IC Pipeline Failures

Considers Key"Blind-Spot"

Integrity Hazards

-

Detrimental Well Start-ups

-

Biomass Debris Ingress

-

-

Intermittent / Cyclic Operations

-

Non-Conforming Wet-Gas

-

Episodic Delivery of Tank Bottom Sludge

-

Oxygen Ingress

-

Tank Farms / Trucked-In Deliveries

-

QIC Assess Pin-Points Locations of Most Probable Corrosion Damage

QIC ASSESS internal corrosion hazard profiling service has been recognized as the industry-leading foundation for the design of hazard-optimized mitigation strategies within a formal Corrosion Management Plan (CMP-IC) since 1994